We love being part of your mission to heal.

At World Air Cargo, every member of our team understands the need to respect the integrity of your pharmaceutical shipments.

We personally care for your products while in our custody with our highly trained and dedicated staff, refrigerated trucks, controlled storage facilities, temperature-controlled container options, and always cooperate with IATA CEIV Pharma approved Airlines.

State-of-the-art solutions to ensure your cargo arrives in perfect condition

World Air pharma Active

The solution for time and temperature sensitive pharmaceutical products that need to be shipped in active containers. A variety of containers is used to keep healthcare goods as protected as possible, including dry ice technologies. Goods shipped are kept at a constant temperature throughout the entire cargo journey. Use of active containers mitigates risks for ambient temperature influence on healthcare products.

World Air pharma Passive

Passive solutions for pharmaceutical shipments

In addition to your own autonomous packaging, we offer main temperature ranges solutions such as COL (+2+8°C) CRT (+15+25°C) and ERT (+2+25°C).

Our passive solution provides storage handling into qualified and yearly calibrated cool rooms according to your temperature range specification. We ensure minimizing breaks in the chain by providing short time SLA as well as temperature controlled holds while inflight.

To make sure passive cargo is kept at the required temperature between aircraft and the cool facilities, pre-cooled thermal blankets are used which stabilizes the environment of the shipment shielding it from extreme weather and temperature fluctuations.

Constructed from a double layer of waterproof PVC material, the blanket can be used as a primary or secondary protection. Pharmaceutical cargo is positioned in the aircraft to allow for quick off loading and priority movement to the cool facilities in the hub.

- Pre-cooled in +2°C to +8°C cool room before applied to maximize effectiveness

- Protection up to 45 minutes at 45°C

- Minimizes temperature shocks

- Sealed with Velcro for quick attaching and removal

- Extensively tested

Data loggers to give you 100% transparency of our cold chain integrity

At World Air Cargo we understand that some of our customers wish to get additional guarantee of their special cargo integrity with the usage of data loggers.

Almost all data loggers contain lithium batteries and some of them can be equipped with GPS/GSM modules which under certain circumstances can influence aircraft avionic system and cause fire on board. Taking this into consideration, we have established approval procedure for any data loggers that accompany cargo during transportation.

Popular Active containers for a seamless and efficient healthcare journey

Envirotainer RAP e2 container

The RKN e1 is a one-pallet size container. Based on a second-generation active temperature control system, it uses compressor cooling and electric heating technology to meet the requirements of the pharmaceutical industry for smaller shipments.

The RKN e1 container maintains product temperatures in the +2 to +8 °C range, controlled room temperature (+15 to +25 °C) range or at any chosen set temperature between ±0 to +25 °C.

It has an insulated container shell, enhanced air circulation, electric heating and compressor cooling, as well as one energy source and batteries that can be recharged at standard AC power connection points. The RKN e1 container also offers data-logging functionality.

Envirotainer RAP t2 container

The Envirotainer RAP t2 container provides accurate and reliable protection for large shipments of temperature-sensitive products.

With an external dimension of 3170mm (L) x 2230mm (W) x 1620mm (H), the RAP is the largest container in the Envirotainer fleet. The RAP can only be forklifted when empty and is most commonly handled with roller beds.

The Envirotainer RAP t2 container features Envirotainer’s proven dry-ice-based active temperature control system and enables air transportation of both frozen and chilled product

The Envirotainer RAP t2 container provides accurate and reliable protection for large shipments of temperature-sensitive products.

With an external dimension of 3170mm (L) x 2230mm (W) x 1620mm (H), the RAP is the largest container in the Envirotainer fleet. The RAP can only be forklifted when empty and is most commonly handled with roller beds.

The Envirotainer RAP t2 container features Envirotainer’s proven dry-ice-based active temperature control system and enables air transportation of both frozen and chilled product

Envirotainer RKN t2 container

The Envirotainer RKN t2 container provides accurate and reliable protection for shipments of temperature-sensitive products.

With an external dimension of 2000mm (L) x 1535mm (W) x 1620mm (H), the RKN is the medium-size container in the Envirotainer fleet. The RKN can be forklifted.

The Envirotainer RKN t2 container features Envirotainer’s proven dry-ice-based active temperature control system and enables air transportation of both frozen and chilled products.

CSafe RKN

The RKN is the only compressor-driven refrigeration unit with precise temperature management of +4°C to +25°C . The robust insulation and thermal capabilities will withstand extended hold times and delays in transit.

The battery life is over 100 hours at +25°C and, because there is no dry ice, there are no special handling charges or charges for hazardous goods. In addition, the data tracking device monitors and verifies the payload temperature to aid regulatory compliance and data is easily downloadable via a USB.

The CSafe RKN is certified by the FAA, EASA, Transport Canada, Hong Kong CAD, Irish Aviation Authority and Australian CASA.

CSafe RAP

The CSafe RAP is the latest innovation in high-performing temperature controlled containers that combines innovative heating and compressor-driven cooling technologies with advanced VIP insulation to eliminate the risks associated with extreme ambient conditions (-30°C to +54°C) and long-duration shipments.

User-selectable temperature set points from +4°C to +25°C in 1°C increments, with a battery run time of up to 120 hours.

Automated data from 10 temperature sensors is available to download to a USB directly from the container.

The CSafe RAP is certified by the FAA, EASA, Transport Canada, Hong Kong CAD, Irish Aviation Authority and Australian CASA.

DoKaSch Opticooler RAP

With quadruple redundancy for all critical components, the DoKaSch Opticooler RAP container reliably controls temperatures within the range of +2°C to +30°C.

Its touchscreen control panel makes it easy to use and it’s also cost-effective; with space for up to five Euro pallets or four US pallets.

With an extremely large battery capacity, highly advanced compressor technology and integrated CPU, the Opticooler outperforms all comparable units. The battery charging time is between two to four hours and the container does not require dry ice.

DoKaSch Opticooler RKN

The Dokasch Opticooler RKN is reliable, cost-effective and user-friendly, with a large battery capacity, advanced compressor technology and integrated CPU, as well as a touchscreen control panel.

With space for one Euro pallet or one US pallet, the container reliably maintains temperatures within the range of +2°C to +30°C.

The battery charging time is between two to four hours and the container does not require dry ice.

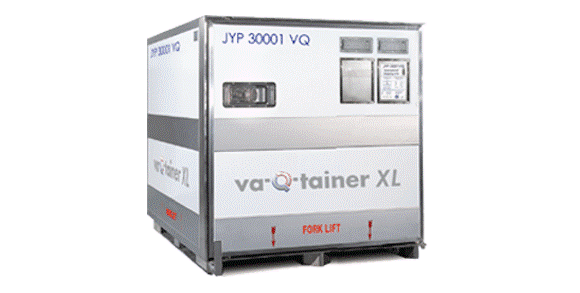

Va-Q-tec

The va-Q-tainer is a high-performing rental container which incorporates vacuum insulation and phase change materials to maintain the required temperature for more than five days. va-Q-tec’s Advanced Passive Alternative is delivered to you quality-checked and preconditioned, ready to LOAD & GO. The LOAD & GO Service simplifies the container handling during product loading and unloading as well as during transport, providing a reliable packaging solution for the most challenging trade lanes.

The single and double pallet solutions from va-Q-tec allow customers efficient use of payload space, preserving the efficacy, quality and value of pharmaceutical and biological products with one configuration for all seasons and hemispheres, not requiring power supply, fans or batteries.

Six temperature ranges from -40 to +25°C with PCM Elements, or up to -70°C with dry ice

Constant temperature, easy handling, low risk and high reliability

Performance at +2°C - +8°C from 120 to 230 hours

Skycell

Hybrid Containers from Skycell

SkyCell’s hybrid containers combine hardware and software through the expertise of Swiss precision engineering. As safe, secure and sustainable solutions, they have been engineered to ensure lifesaving vaccines and medicines reach patients on time and in pristine condition

SkyCell C/CRT containers

The SkyCell C container maintains a temperature of +2°C to +8°C, while its CRT counterpart sustains +15°C to + 25°C respectively. Choose from 1 x EU-PAL or 1 x US-PAL (1500 model) to 2 x EU-PAL (2500 model). Each one is GDP certified, quality checked and delivered ready to use, with an average runtime of 202hrs (8.4 days), IoT sensors, and an audited performance of less than 0.1% temperature excursion rate. Plus, you can prolong the runtime by placing it in a cool environment (reefer truck or temperature controlled warehouse) where it can self-charge automatically.

SkyCell 1500F containers

For colder solutions and frozen transport, SkyCell has developed the F container. It is a safe, secure and sustainable container solution that doesn’t use dry ice.

SkyCell’s frozen container offers a long independent runtime of -15°C to -30°C with a light weight of only 484kg. This is a strong feature as its lighter weight has a beneficial impact on the overall rate. With an average runtime of 120hrs, this can ensure that all medicines and vaccines are safeguarded throughout extended journeys. The F container is available as 1x EU-PAL or US-PAL.

Engineered for cold transport, this frozen container protects pharma products from extreme temperatures, humidity, shock and vibrations

SkyCell 1500DF containers

SkyCell’s innovative approach to deep frozen pharma protection, the DF container ensures biologics remain in pristine condition throughout the entire journey. For medicines and vaccines that need extremely low temperatures to be kept intact, this is the ideal solution.

SkyCell’s deep frozen container ensures a steady temperature between -80° to -60°C and has an independent runtime of 120hrs. With containers sizes from 1 x US/EU-PAL, it features only 100kg of dry ice, significantly less than most deep frozen alternatives and is easy and safe to handle.